Product Details

Description

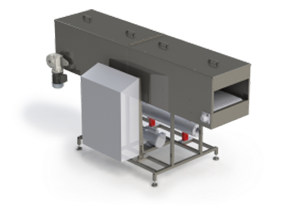

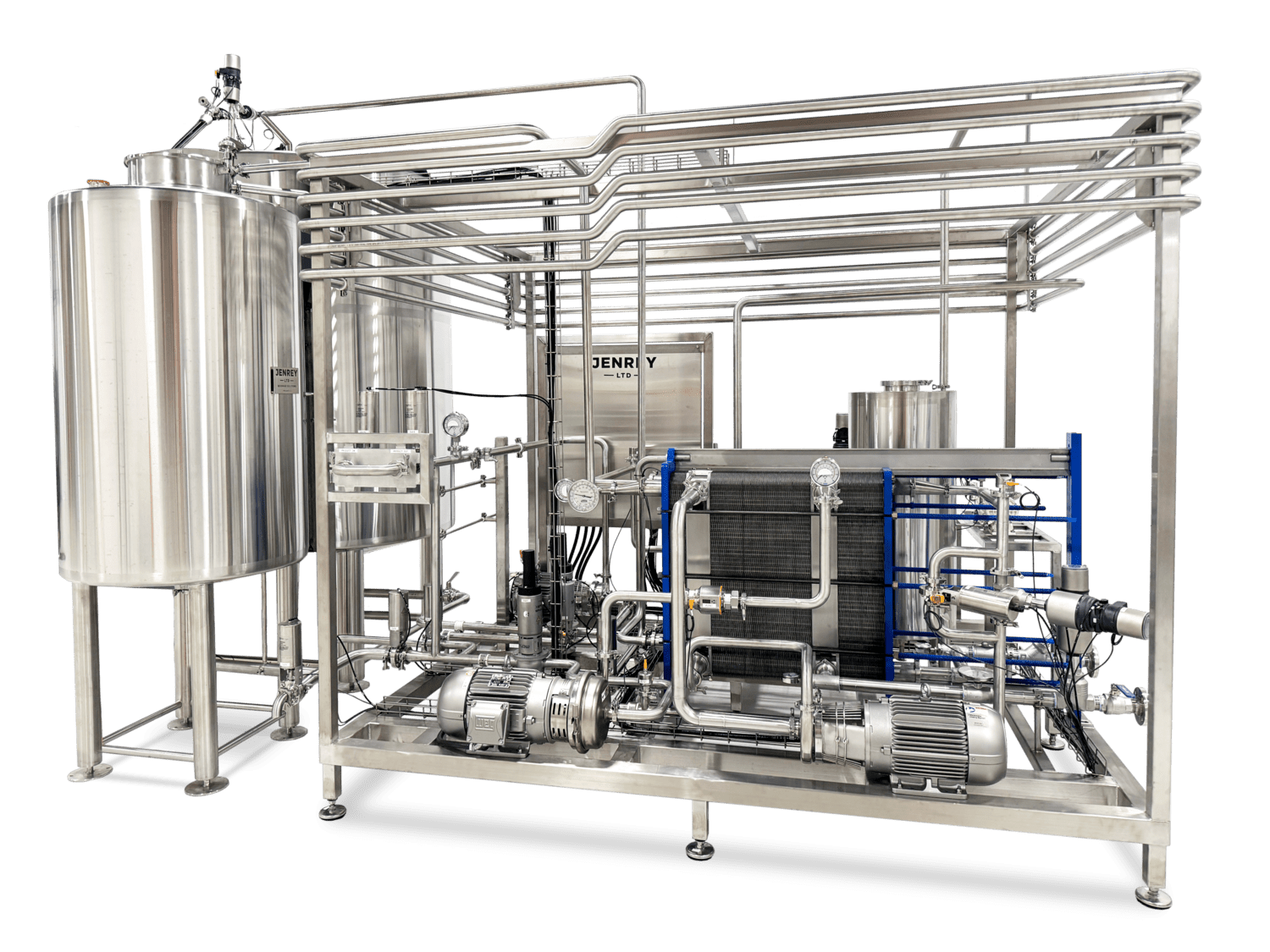

Our hybrid tunnel pasteurizer is for aluminum cans only and pulls from the design fundamentals of our non-regenerative ‘Tunnel of Love’ and our fully regenerative tunnel pasteurizers. While still maintaining a small, compact footprint this type of tunnel includes regenerative pre-heat and pre-cool zones thereby reducing the glycol cooling requirement by 40%. The hybrid option is a perfect fit for the canning operation that values more efficiency while accepting a slightly larger footprint for any given throughput rate. A key scenario that validates hybrid tunnel integration is a lack of glycol cooling capacity available to meet a non-regenerative tunnel’s requirement or the need to allocate glycol chiller capacity to other processes so not to add additional cooling capacity in the future.

As the product moves through the tunnel it will travel through 4 stages/zones. They are in order, a regenerative pre-heat zone, heating and holding zone, a regenerative pre-cool zone and finally a cooling zone. The regenerative nature of this design achieves a more gradual product temperature ramp up and cool down and cuts the cooling requirement nearly in half by capturing the cold product temperature of the cans entering the tunnel.

Technical Data

Hybrid Regenerative Design

Small Footprint Systems

Easy to Maintain and Service

Touchscreen Controls and Automation

Includes Can ‘Warmer' Function

Uniform, Clog-Free Spray Nozzles

304 Stainless Steel Fabrication

Accessible Sump Access and Clean Out

Steam, Hot Water and Electric Heating Options

Full Scope Integration with New or Existing Packaging Lines

Available with throughputs ranging from 25 to 300 cpm

Utility Requirements

- Heating - Steam or Hot Water

- Cooling - Glycol Cooling

- Power - various voltage options, to be specified by the customer.

- Air - compressed air @ 85 psi

- Water - supply water 40-60 psi

Heating and Cooling Utility Requirements Vary By Tunnel Size

Other Products

Non-Regenerative Tunnel Pasteurizers

Pasteurization is a process of heating beer, and many other consumable products, to a temperature that will kill any living microbes without changing the chemistry or flavour.

View Product

Tunnel Warmers

Tunnel Warmer is designed and built to significantly reduce and eliminate moisture and condensation on your cans after filling.

View Product

Semi-Auto Keg Washer/Filler

This machine is equipped with two heads and three tanks. The first head is for cleaning and the second head is for filling. The three tanks are for caustic, acid and recovered water, which ensures we follow best practices in kegging and adds an extra level of efficiency, while minimizing waste water.

View Product

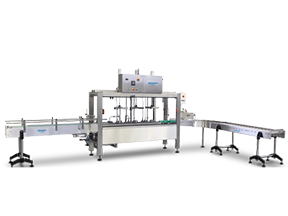

Fully Automated Keg Lines

The series of machines are all fully automatic and can vary from 2 heads to 8 head modular systems which are custom built to suit your specific needs.

View Product

CJ1 Keg Filler

The Jenrey CJ1 machine is a dedicated filler designed and priced to bridge the gap between manual filling and a fully automatic machine and can be used to fill Steel Kegs or plastic One Way Kegs!

View Product

Cooling Tunnels

Our Cooling Tunnels are designed to provide precise, controlled cooling for a wide range of products, ensuring they reach the ideal temperature for packaging, storage, or distribution.

View Product

Flash Pasteurizers

Preserving Quality, Extending Shelf Life, Ensuring Product Control and Consumer Safety! Unlock the power of cutting-edge technology in beverage production with our state-of-the-art Flash Pasteurizer.

View Product

Regenerative Tunnel Pasteurizers

Pasteurization is a process of heating beer, and many other consumable products, to a temperature that will kill any living microbes without changing the chemistry or flavour.

View Product

Hybrid Tunnel Pasteurizers

Pasteurization is a process of heating beer, and many other consumable products, to a temperature that will kill any living microbes without changing the chemistry or flavour.

View Product