Is quality assurance and consistency top of the list in your small business? Are you constantly worrying about spoiled product or packaging problems? In addition to being integral to producing safe non-alcoholic and low ABV options pasteurization is important to craft a quality product with a long lasting shelf life.

Beverage pasteurization is a thermal process designed to eliminate or significantly reduce the number of microorganisms (such as bacteria, yeasts, and moulds) present in beverages. The primary objective is to make the beverage safer for consumption by extending its shelf life and reducing the risk for food-borne illnesses and hard working being poured down the drain.

The pasteurization process involves heating the beverage to a specific temperature for a determined period and then rapidly cooling it. The goal is to destroy pathogenic microorganisms without causing significant changes in the taste, nutritional content, or quality of the beverage. Pasteurization is commonly used in the production of various types of beverages, including juices, milk, wine, beer, cider, and other alcoholic & non-alcoholic drinks.

There are different methods of pasteurization, and the choice of method depends on factors such as the type of beverage, container size, and desired characteristics of the final product. Some common pasteurization methods include:

Tunnel pasteurization (#tunneloflove)

Tunnel pasteurization is a method of pasteurizing beverages that involves passing containers of the beverage through a heated tunnel. This process is commonly used for heat-sensitive liquids, such as certain types of juices, beer, cider and other beverages. The goal is to heat the beverage to a temperature that is sufficient to kill or inactivate harmful microorganisms without significantly affecting the taste or quality of the product.

The tunnel pasteurization process allows for continuous and efficient pasteurization of large quantities of beverages and can be considered a final kill-step. The precise parameters, such as temperature and dwell time, are carefully controlled to meet requirements and to achieve the desired level of microbial inactivation. (Target PU’s – Pasteurization Units)

Tunnel pasteurization is a widely used method in the food and beverage industry, providing an effective means of ensuring product safety and extending the shelf life of beverages while maintaining their quality.

Flash Pasteurization

Also known as high-temperature, short-time (HTST) pasteurization, is a rapid heat treatment process used to pasteurize beverages. The method involves exposing the liquid to a high temperature for a short duration, effectively killing or reducing the number of harmful microorganisms without significantly altering the taste or nutritional content of the product.

Here’s a basic overview of the flash pasteurization process:

Heating: The beverage is quickly heated to a high temperature, typically around 71.7°C (161°F). This temperature is maintained for a short time, usually 15 to 20 seconds. The rapid heating and short exposure time help minimize the impact on the sensory and nutritional qualities of the beverage.

Cooling: Following the brief exposure to high temperature, the beverage is rapidly cooled to halt the pasteurization process. This quick cooling prevents any undesirable changes that might occur if the product was subjected to prolonged heat treatment. Flash pasteurization is an efficient method for preserving the quality of heat-sensitive beverages because it minimizes the time the product spends at elevated temperatures

WHY Pasteurization?

Efficiency: This is a continuous process, allowing for high-throughput production. Beverages are conveyed through a heated tunnel, enabling a consistent and efficient treatment of large quantities of product.

Preservation of Product Quality: The heating and cooling cycles of tunnel pasteurization help preserve the sensory and nutritional qualities of the beverage.

Consistency: The controlled environment of the tunnel ensures that the pasteurization parameters, including temperature and dwell time are consistently maintained. This contributes to the reliability of the process and the consistent quality of the final product.

Extended Shelf Life: Tunnel pasteurization effectively reduces microbial loads, contributing to an extended shelf life for the pasteurized beverages. This can enhance product stability and reduce the risk of spoilage.

Regulatory Compliance: Tunnel pasteurization is designed to meet regulatory requirements for food safety. The controlled and monitored process helps ensure that the pasteurization conditions are sufficient to eliminate or reduce harmful microorganisms, meeting industry standards and regulations.

Cost-Effectiveness: The efficiency and speed of tunnel pasteurization can contribute to cost savings in terms of production time and energy consumption. The continuous nature of the process allows for economies of scale, making it a cost-effective option for large-scale beverage production.

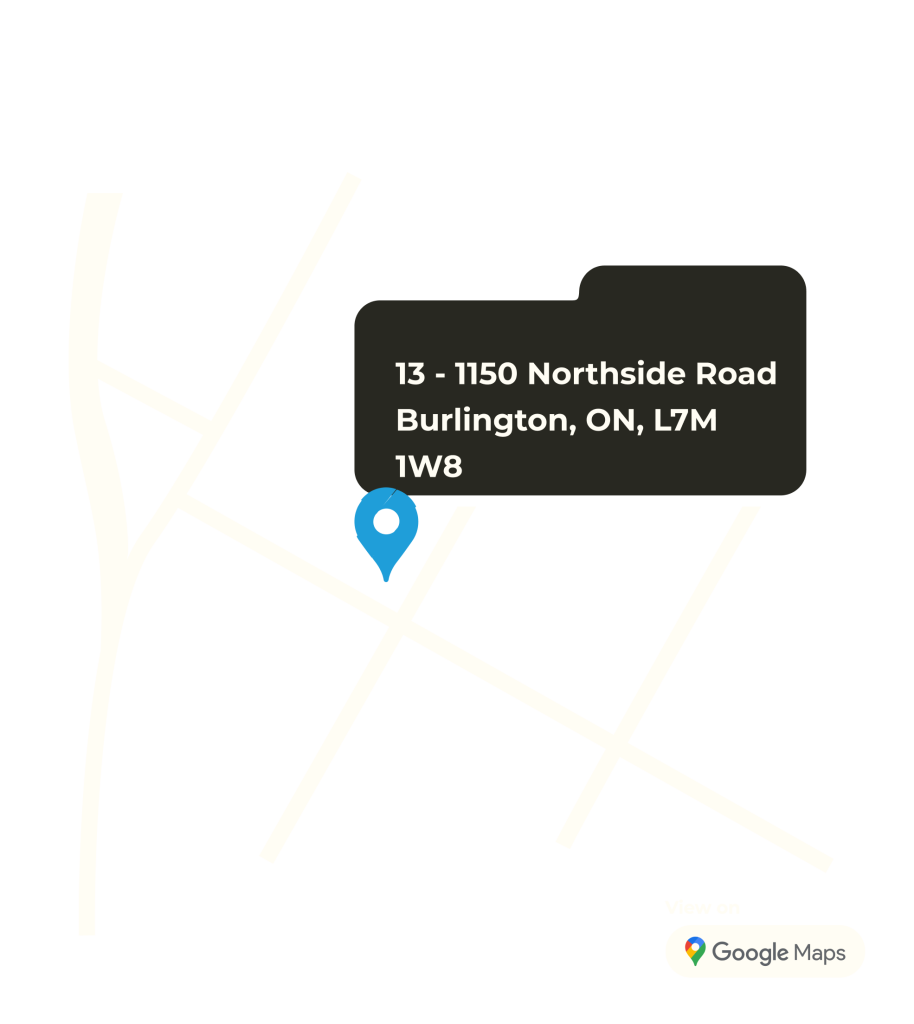

Tunnel of Love

Designed and built in Burlington Ontario the Jenrey Ltd Tunnel of Love, tunnel pasteurizer is modelled to have the smallest footprint in the industry and custom built to fit the capacity of your operations. These machines create accessibility for pasteurization for all size operations and limitations. As well, the Jenrey Can Warmer is designed and built to significantly reduce and eliminate moisture and condensation on cans after filling. This will ensure the cans and carrier are free from condensation, avoid any chance of bacteria growth and maintain the full integrity of the packaging for shipping and distribution.

Want to learn more? Reach out to Jenrey Ltd and chat all things pasteurization today!