Fermentation (UNI)

TANK

All tanks come fitted with glycol jackets for cooling and an adjustable racking arm that allows for efficiency and maximum product recovery. In addition, a minimum 25 – 30% head space provides space for high krausen or vigorous fermentations without foam losses.

PRODUCT DETAILS

Description

Certified stainless-steel material and sanitary construction is our standard. All tanks are insulated for efficiency and custom fabricated to meet your specific space and height requirements.

Our standard tanks range in sizes from:

– 3BBL to 160BBL

– 3HL to 160HL

*Larger or custom tanks available on request

Specification

Vessel working pressure: 14.5 PSI (tested to 30 PSI)

Jacket working pressure: Tested to 30 PSI

Interior weld finish: stain removed, polished on a regular margin and acid cleaned.

Exterior weld finish: stain removed and brightened on a regular margin.

Jackets are sized to cool the working volume from 65F to 34F in 24 hours using a glycol inlet temperature: 30F.

80mm PU foaming Insulation for side and bottom.

tank placed in a mild steel cradle for shipping.

Minimum additional head space 25 - 30%

Shell material 304 2b SS

Cladding material 304 brushed #4 SS

Relief pressure: 15 PSI

4 Legs c/w adjustable Footpads.

Formed dish head.

60 degrees cone bottom

Top Fitting

- CIP spray ball on 1.5" side arm with CIP end piece(including gauge, ball valve, quick disconnector)

- 2.5" PVRV

- Manway (top or side available)

- 6” hop addition port available

Side Fittings

- Glycol jackets

- Thermowell

- Sample port

- Manway (top or side available)

Cone Fittings

- Drain & valve

- Rotatory arm & valve

- Glycol couplings.

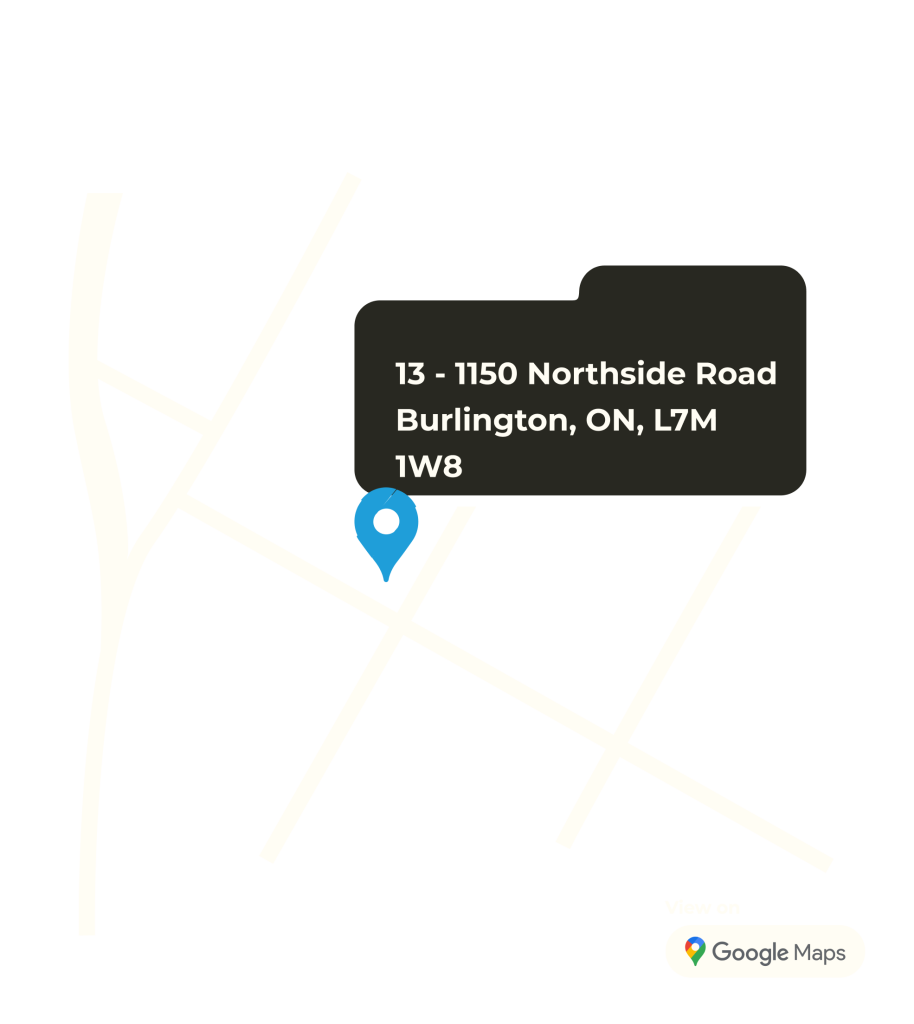

Pricing Enquiries?

CONTACT US

Other Products

Tunnel Pasteurizers

Pasteurization is a process of heating beer, and many other consumable products, to a temperature that will kill any living microbes without changing the chemistry or flavour.

View Product

Tunnel Warmers

Tunnel Warmer is designed and built to significantly reduce and eliminate moisture and condensation on your cans after filling.

View Product

SEMI-AUTO KEG WASHER/FILLER

This machine is equipped with two heads and three tanks. The first head is for cleaning and the second head is for filling. The three tanks are for caustic, acid and recovered water, which ensures we follow best practices in kegging and adds an extra level of efficiency, while minimizing waste water.

View Product

Fully Automated Keg Lines

The series of machines are all fully automatic and can vary from 2 heads to 8 head modular systems which are custom built to suit your specific needs.

View Product

FULTON Classic Steam

The Classic™ steam boiler represents the evolution of Fulton’s original vertical tubeless boiler design.

View Product

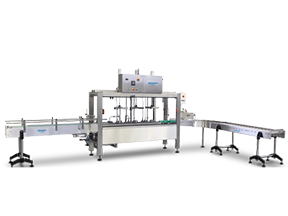

CJ1 KEG FILLER

The Jenrey CJ1 machine is a dedicated filler designed and priced to bridge the gap between manual filling and a fully automatic machine and can be used to fill Steel Kegs or plastic One Way Kegs!

View Product

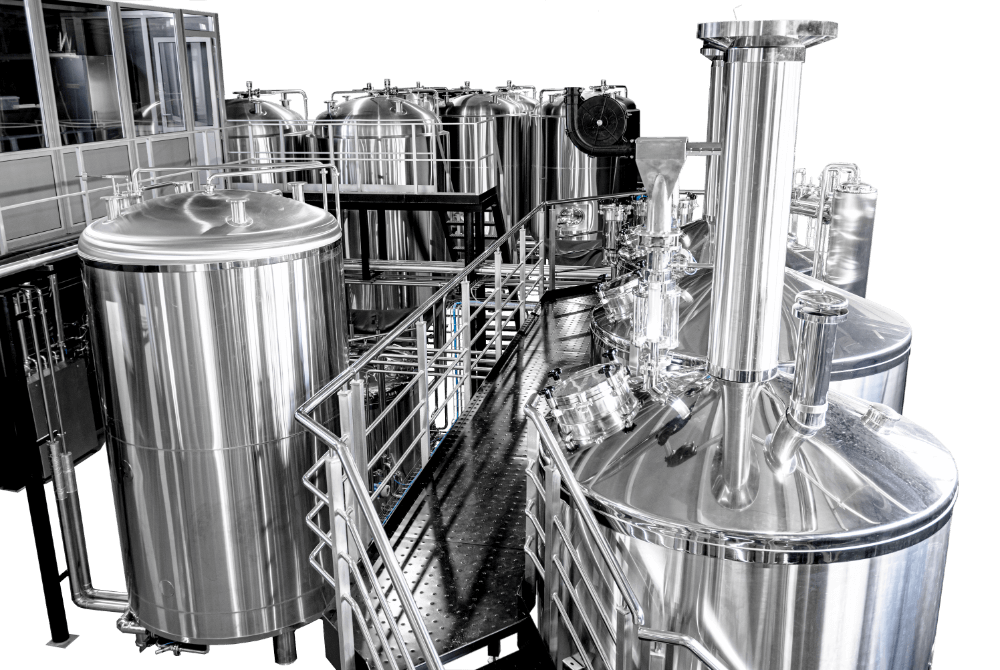

BREWING SYSTEM

Our brewhouses are designed to meet the needs of your process from beer, tea or brewing for distillation to mixing and blending.

View Product

Cellar Vessels

All tanks come fitted with glycol jackets for cooling. Minimum 25 – 30% head space provides space energetic fermentations without foam loses.

BRITE TANKS

FERMENTATION TANKS

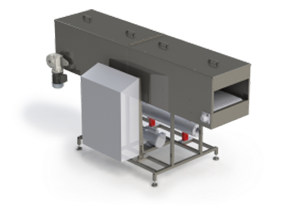

Cooling Tunnels

Our Cooling Tunnels are designed to provide precise, controlled cooling for a wide range of products, ensuring they reach the ideal temperature for packaging, storage, or distribution.

View Product