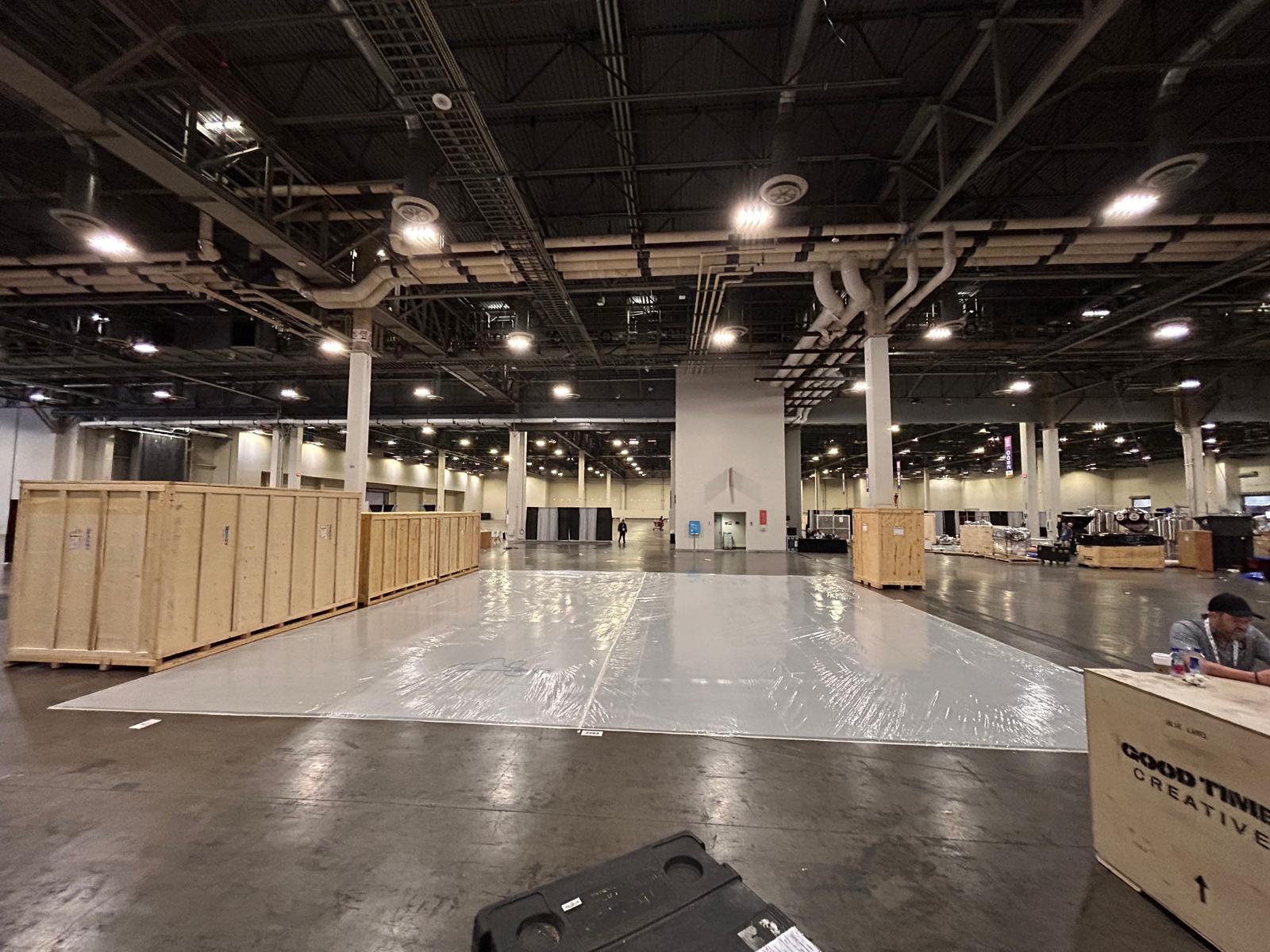

Craft Brewers Conference & Beer Expo 2024 – Las Vegas

This week we exhibited a few of our favourite things at the Craft Brewers Conference and Beer Expo in Las Vegas, Nevada. We can’t believe it’s been a year since we were in Nashville for last years CBC’s showcasing our 50 can per minute tunnel pasteurizer, semi automatic keg washer/filler and a 4 vessel, 20 BBL automated brewhouse. For this years show we decided to jack things up and bring two tunnel pasteurizers, a 25 can per minute and 100 can per minute, allowing us to demonstrate our ability to match your unique needs, with a custom footprint machine. As well this year we showcased a 2 vessel, 10 BBL automated brewhouse.

Pasteurization/Industry Conversations

The networking aspect of this show is unlike any other. Not only are we able to talk about what we do/who we are, we are able to connect and learn about industry trends and new growth from the front-line perspective. Overall, since last year it’s clear that the topic of non-alcoholic is dominating the sector currently. As a team we engaged in so many great informative, objective conversations and inquiries about our pasteurization. The industry has changed greatly in as little as a year since the last CBC’s. Co-packing has surged and co-packers and breweries alike have broadened their production scope to non-alcoholic beer or beverage as a whole to diversify their offering and compete in different sectors. Pasteurization is a key component to this operation step for non -alcoholic beverage production, expanding distribution or looking to improve quality or shelf stability.

Thank you to everyone who stopped by the booth for a chat, there weren’t many breaks and we barely have our voices left but all conversations were very engaging and we loved to see this level of interest in the equipment we manufacture.

How can tunnel pasteurization help?

As the product moves through our Tunnel of Love tunnel it is heated to a pasteurization temperature of 66°C (150°F) and held at that temperature for a defined period of time before being cooled back down to stop pasteurization. The amount of time that the product is held at 66°C (150°F) is determined by the production team and is measured in pasteurization units (PU’s) where one PU is the lethal effect on micro-organisms obtained by holding product for one minute at 66°C (150°F). Our easy-to-use interface allows for efficient observation and manipulation as necessary during this process.

All of our systems are modular single deck pasteurizers so as your production demand grows, your system can grow with you by adding sections to increase capacity.