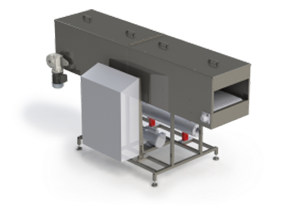

Non-Regenerative Tunnel Pasteurizers

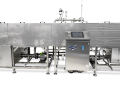

The Tunnel of Love

Product Details

Description

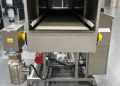

This is our flagship line of equipment, a small footprint, can-only non-regenerative tunnel pasteurizer. Designed to integrate in small spaces, oftentimes on production floors that weren’t originally laid out to have a tunnel pasteurizer. As the craft beverage industry changes the Tunnel of Love has facilitated pasteurization in craft beverage production facilities allowing our customers to innovate and adhere to the demands of an ever evolving industry. We build these tunnels to pasteurize throughput rates of 25 – 300 cpm with multiple PU (pasteurization unit) capability options.

As the product moves through the tunnel it is heated by circulating water to a manipulatable pasteurization temperature in the heating zone and held at that temperature for a defined period of time. It is then cooled back down in the cooling zone to stop pasteurization and return the product to a suitable handling temperature.

The holding time and temperature at which the product is pasteurized is often determined by an accredited lab or process authority and assured by the production staff, It is measured in pasteurization units (PU’s) by a data logger, included in our tunnel pasteurizer scope of supply. Our easy-to-use, touch screen interface allows for efficient observation and manipulation as necessary during this process, and recipes can also be saved for repeated use.

Talk to our sales team to help identify which size tunnel is right for your operation, and ask about our buy-back program for the Tunnel of Love. We want to help you grow your operation with our thermal processing solutions.

Technical Data

Small Footprint Systems

Easy to Maintain and Service

Touchscreen Controls and Automation

Includes Can ‘Warmer' Function

Uniform, Clog-Free Spray Nozzles

304 Stainless Steel Fabrication

Accessible Sump Access and Clean Out

Steam, Hot Water and Electric Heating Options

Easily Integrated into Existing Canning Lines

Available with throughputs ranging from 25 to 300 cpm

Eliminate the Steam and Electric Heating Bubbles, instead…

Utility Requirements

- Heating - Steam, Hot Water or Electric

- Cooling - Glycol

- Power - various voltage options, to be specified by the customer.

- Air - compressed air @ 85 psi

- Water - supply water 40-60 psi

Heating and Cooling Utility

Requirements Vary By Tunnel Size

Other Products

Non-Regenerative Tunnel Pasteurizers

Pasteurization is a process of heating beer, and many other consumable products, to a temperature that will kill any living microbes without changing the chemistry or flavour.

View Product

Tunnel Warmers

Tunnel Warmer is designed and built to significantly reduce and eliminate moisture and condensation on your cans after filling.

View Product

Semi-Auto Keg Washer/Filler

This machine is equipped with two heads and three tanks. The first head is for cleaning and the second head is for filling. The three tanks are for caustic, acid and recovered water, which ensures we follow best practices in kegging and adds an extra level of efficiency, while minimizing waste water.

View Product

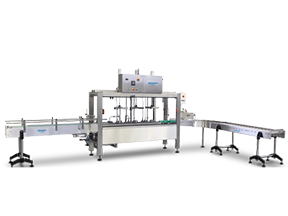

Fully Automated Keg Lines

The series of machines are all fully automatic and can vary from 2 heads to 8 head modular systems which are custom built to suit your specific needs.

View Product

CJ1 Keg Filler

The Jenrey CJ1 machine is a dedicated filler designed and priced to bridge the gap between manual filling and a fully automatic machine and can be used to fill Steel Kegs or plastic One Way Kegs!

View Product

Cooling Tunnels

Our Cooling Tunnels are designed to provide precise, controlled cooling for a wide range of products, ensuring they reach the ideal temperature for packaging, storage, or distribution.

View Product

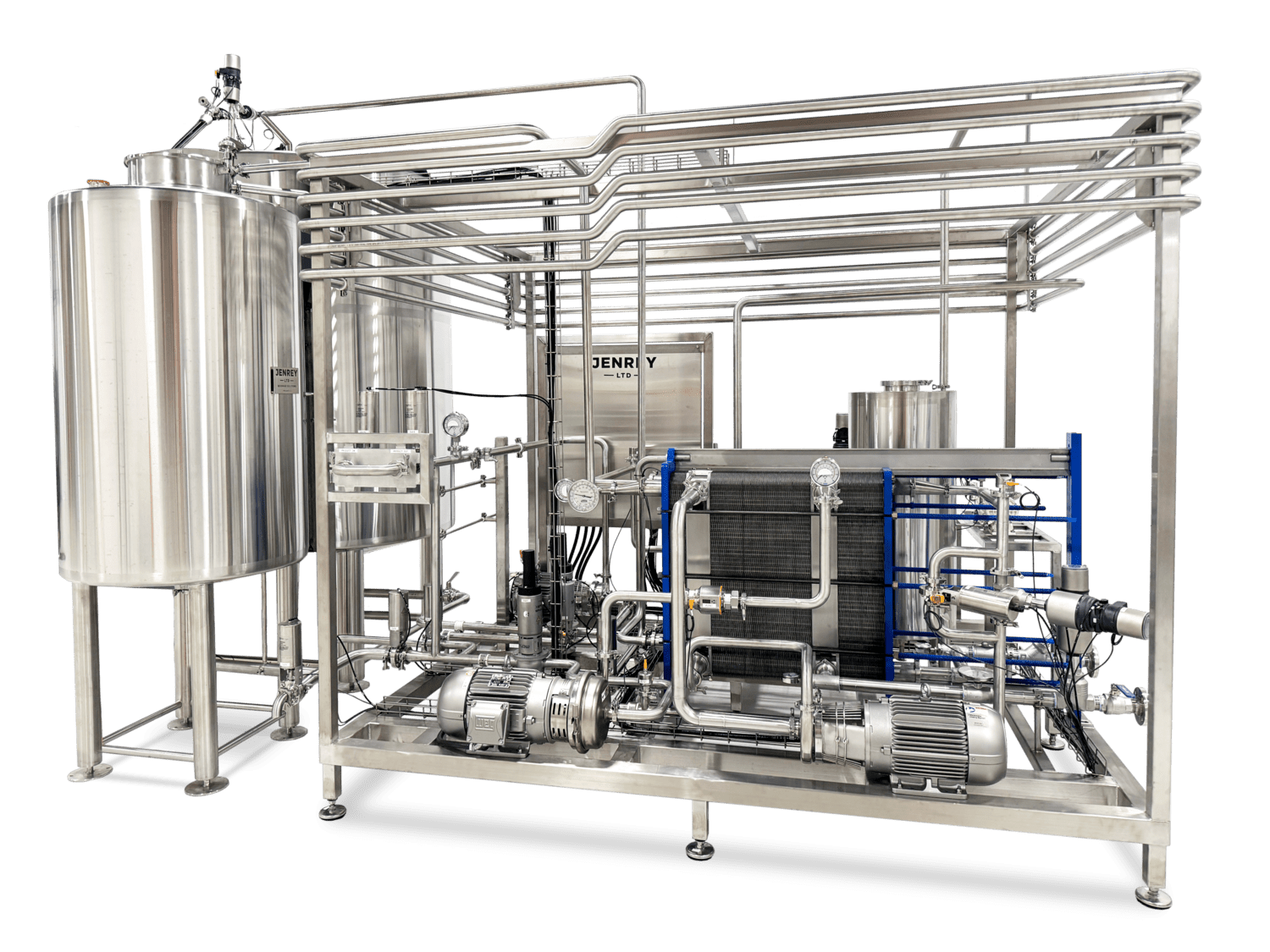

Flash Pasteurizers

Preserving Quality, Extending Shelf Life, Ensuring Product Control and Consumer Safety! Unlock the power of cutting-edge technology in beverage production with our state-of-the-art Flash Pasteurizer.

View Product

Regenerative Tunnel Pasteurizers

Pasteurization is a process of heating beer, and many other consumable products, to a temperature that will kill any living microbes without changing the chemistry or flavour.

View Product

Hybrid Tunnel Pasteurizers

Pasteurization is a process of heating beer, and many other consumable products, to a temperature that will kill any living microbes without changing the chemistry or flavour.

View Product